Industrial Automation refers to using control systems, such as computers, robots, and information technologies, to handle different processes and machinery in industry. Value Delivery 4.0 demands that we transform our industrial-era ideas of replacing humans to augment human beings. It is a step beyond mechanization, where human operators were once provided with machinery to assist them in physical work; new requirements must empower fewer people in the workforce due to a lower population. Look to Japan and other developed nations as a reference.

The primary goals of industrial automation are to improve productivity and quality while reducing errors and waste, enhancing safety, and adding flexibility to a physical or digital manufacturing system. That is changing to a value delivery process. Automation can be achieved through various means, but the new world of hybrid systems and pervasive computing will force us to rethink what automation is going forward.

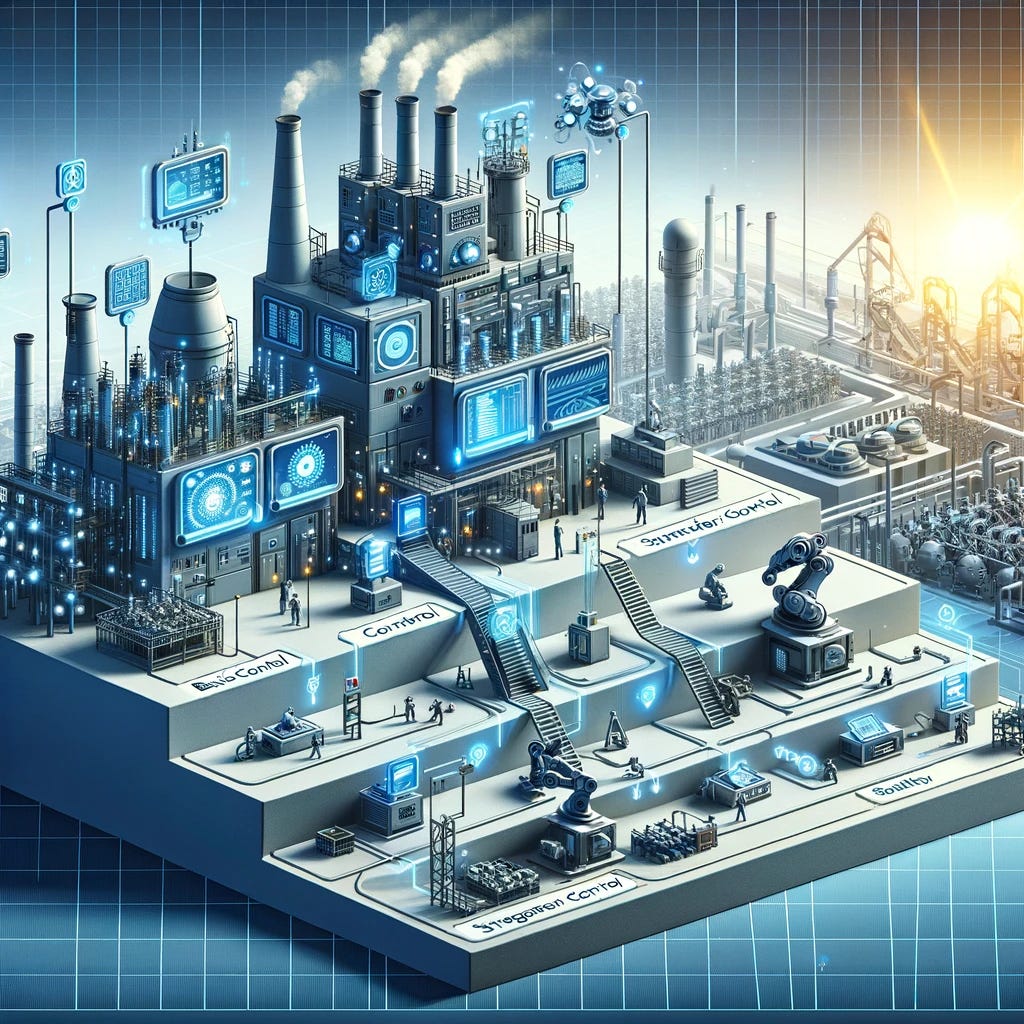

There are different levels of automation in industrial settings:

1. Basic Control: This involves simple controls or mechanisms, like on/off switches, that aid in operating machines and systems. Pervasive computing will develop and use context to set the values for this in the future.

2. Supervisory Control: This utilizes software systems to direct and manage the processes, often involving SCADA (Supervisory Control and Data Acquisition) systems for real-time monitoring and control. Expanding this into the age of pervasive computing needs a new model, but the principal value is the same. How do we monitor, control, and secure everything we have built?

3. Integrated and contextual automation: This is a more advanced level, where various systems are integrated harmoniously, often involving complex robotics and control software to manage the entire value delivery process.

Industrial automation's impact is profound, and omnipresent computing's is exponential. Numerous benefits await us, such as increased value delivery speed and efficiency, higher consistency and quality, reduced human error, and lower operational costs. However, it also presents challenges, including the displacement of workers, the need for skilled personnel to manage automated systems, significant initial investment costs, and the risks of creating the wrong context. Read my following posts to learn more about this new world being created around us.